About Us

Experience the True Essence

of Indonesian Coffee

The name 70° Fahrenheit Koffie is inspired by the ideal temperature levels for coffee to grow, which serves as a reminder for the past 21 years of our journey to introduce the exquisite quality of Indonesian specialty coffee to the world through #JendelaKopiIndonesia, which translates as “A Window to Indonesian Coffee.”

Established in 2003, our mission is to present quality coffee from the best plantations throughout the Indonesian archipelago. We work closely with our farmers and team to ensure the finest quality of 70° Fahrenheit Koffie beans. We proudly serve the original Balinese Coffee, which is famous for its distinctive flavor and fragrant aroma. Balinese coffee has been recognized for decades as an exotic coffee enjoyed by many coffee fans worldwide and is a must-try when you’re on the island.

Visited by thousands of tourists every year wanting to learn more about Indonesian coffee, we have welcomed many esteemed guests and earned recognition from national and international organizations. You can learn more about Indonesian coffee and the coffee roasting process at 70° Fahrenheit Koffie Roastery in Bali and Batam.

Vision & Mission

Vision

To become the best Indonesian coffee producer with the highest quality of specialty Indonesian coffee.

Mission

- To produce the highest quality Indonesian Coffee for the local and international communities, especially Balinese Coffee.

- To provide an experience and education about Indonesian Coffee to introduce its exquisite quality to the world.

- To help improve the welfare of local communities, especially the farmers and those engaged in the coffee plantation sector.

How We Made

Quality Bean Journey

Strategic Plant Location

The 70°F Koffie factory is located in the Jimbaran area, precisely at Jalan Parigata No. 708 Unud Campus – Jimbaran, Bali. It has a very strategic location, because in addition to having only 15 minutes travel time from Ngurah Rai International Airport, Jimbaran itself is a travelers’ destination with local industries that are visited by many tourists.

Plantation

Production Machines

In the processing of coffee beans, 70°F Koffie uses automated production machines that are handled by experienced personnel. In order to maintain product quality, the handling of the roasting process for each type of coffee bean is also adjusted accordingly.

That ensures that each batch of coffee beans is roasted to perfection, bringing out the unique flavors and aromas specific to each variety. The combination of advanced automation and skilled expertise allows 70°F Koffie to maintain consistency in quality while optimizing efficiency in production. Additionally, strict quality control measures are implemented at every stage, from roasting to packaging, ensuring that customers receive only the finest coffee beans, rich in taste and freshness.

Quality Control

Innovate To Give The Best Results

01

Production Machines

70°F Koffie uses automated production machines that are handled by experienced personnel. In order to maintain product quality, the handling of the roasting process for each type of coffee bean is also adjusted accordingly. That includes special handling requirements such as temperature and length of time required in the roasting process. By putting special attention to this, we are able to produce the perfectly roasted coffee with a good aroma, acidity, body and flavor.

02

Selection Of Raw Coffee Bean

Before being processed in the factory, all incoming coffee beans have gone through a rigorious and layered selection process. It starts from the picking process carried out in plantations where pickers choose matured beans. The selection results are then followed by passing it through field workers for additional quality control, and when it arrives at the factory, it is rechecked again by experts, assessing the quality and content of the water, Besides the selection of quality, we also conduct the selection process for male coffee beans for peaberry coffee products.

03

Production Process

The production process (also called as “roasting”) is carefully conducted and controlled by an expert who has an experience of over 10 years. The involvement of this “master roaster” is very important, because in order to get a consistent and stable coffee quality, sometimes it is necessary to have it manually handled according to each coffee’s characteristics.

04

Quality Product

In addition to internal quality control.

70°F Koffie also ensures the quality of the products by hiring the services of a Q Grader who routinely checks the quality of coffee. A Q Grader is coffee taster, as well as a competent appraiser certified by the Coffee Quality Institute (CQI). With ther involvement, our products are guaranteed to be always in its best quality.

Guest

Our Honored Guest

Visited by His Royal Highness

Juan Jorge de Bagration-Mukhrani and Kristine de Bagration-Mukhrani, Prince and Princess of Georgia.

Visited by Her Highness Shaikha Jawaher, Princess of Bahrain.

Visited by Fish Liew Chi Yu, Malaysian Actress and Model.

Visited by Charles Heung, Hong Kong Actor & Producer.

Visited by Jung Joo Yeon, Korean Actress.

The Chairman of SCAI and the Founder of SCAE (Mr. A. Syafrudin, Mr. Collins Smith).

Awarded by The Indonesian World Record Museum (MURI) for breaking the record of the highest auctioned price of Arabica Coffee.

Participated in Combat Federation Brave 66 in Bali, November 2022.

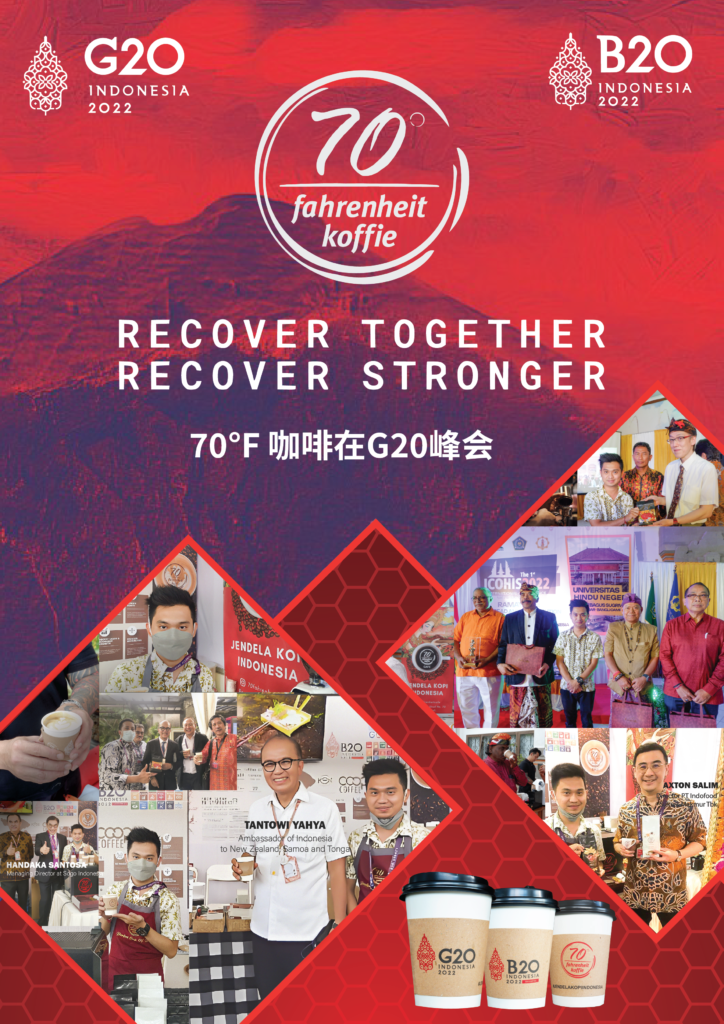

Participated in G20 Conference in Bali, November 2022.